|

296M

Programmable Spectral |

|

This page documents my initial build investigation to reduce the depth of the 296m to less than 3". Since this build the motherboard PCB has been revised to eliminate the interference between the rear mounted resistors and the card connectors. I have also revised and simplified my approach to installing the pins without the headers and the use of Alps 9mm potentiometers. This page is retained for reference information only.

Low Profile Construction

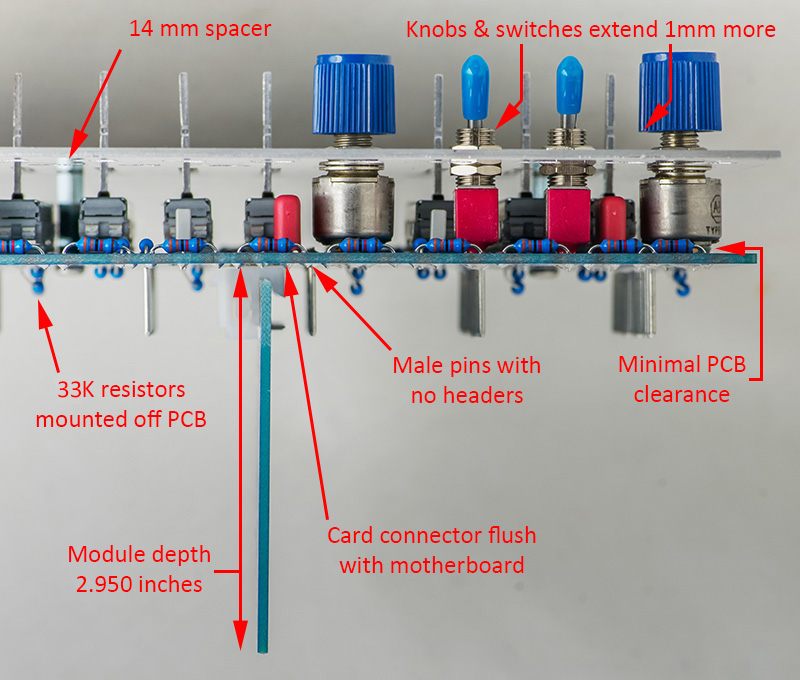

I made a second 296 with the initial MEMS PCBs to investigate lowering the profile to fit a 3" boat. I found that removing the plastic headers from the male pins and using 14 mm standoffs was a reasonable solution. This also requires cutting some plastic pieces from the female headers and mounting some resistors on the motherboard in piggyback.

Low Profile Modifications There are two areas to reduce depth of the module: reducing the height of the front panel spacers and removing the plastic headers from the motherboard pins. While the switches will fit with 12 mm standoffs the PRV6 style potentiometers may not so you will have to check. Reducing the spacers by 3 mm is insufficient to fit a 3" deep boat. The most practical method is to eliminate the plastic headers which saves 0.125" and is the space savings needed. The Molex female connector without the plastic male header provides about 0.080" clearance between the card and motherboard which is ample for most leads and wires but interferes with some of the 33K resistors, wires, and banana jacks.

|

|

I found this the best method for a new PCB build. You can do this after axial components are installed but before the sliders, switches, and potentiometers are installed:

If you have machine tools available you can use this method:

A variation of this method is to pull the plastic header instead of machining it narrower:

Here's half of the pins inserted. It is slow but steady work.

An individual contacted me on their method for eliminating the plastic header. They pressed the plastic header down flush with the bottom of the pins. They inverted the board and installed the pins partially through the PCB. It turns out that a 5.5 mm spacer provides the right spacing so the pins do not extend through the card connectors. They simply tack soldered the end pins, removed the spacers, soldered and cut the pins. This photo shows the header spaced with 5.5mm standoffs on both sides (4 standoffs) prior to tack soldering. This is an easier solution. This image shows four 5.5mm standoffs used as spacers.

If your motherboard is already assembled, then this is likely the only method. |

|

Without the headers the female connectors on the cards slightly interfere with many of the 33K resistors which are close to the rear of the cards. You need to trim off the two plastic tabs between pins 10 and 11 on all cards.

10 of the 33K resistors will slightly interfere with the bottom of the card edge. This doesn't allow the card to be fully seated, but it is sufficient to fit into a 3" deep case using the shorter standoffs (below). To allow full clearance, five of the 33K resistors can be rotated and one lead soldered to a trace and 5 of the resistors need to be lifted and mounted on top of the 22K resistors. Six of the resistors are fine as-is.

Another possibility is to use smaller diameter resistors, 1/8W or Mouser 660-CFS1/4CT52R333J, which should provide ample clearance. (untested). |

|

Removing the plastic header will reduce the depth to 2.96". The card

edges will likely touch the bottom of the boat so make sure there are no screw

heads or any other protrusions which could contact the cards or traces. To gain some

additional clearance the standoffs height can be shortened. |

|

For PRV6 style potentiometers more than 12 mm:

Not Recommended

Substituting 9mm Alpha potentiometers:

|

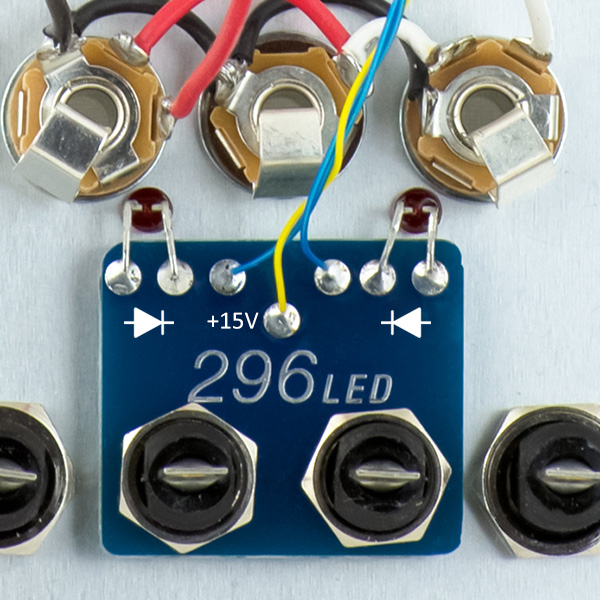

The initial batch of LED boards also had the orientation of the LED backwards. This closeup shows the correct orientation.